Mango

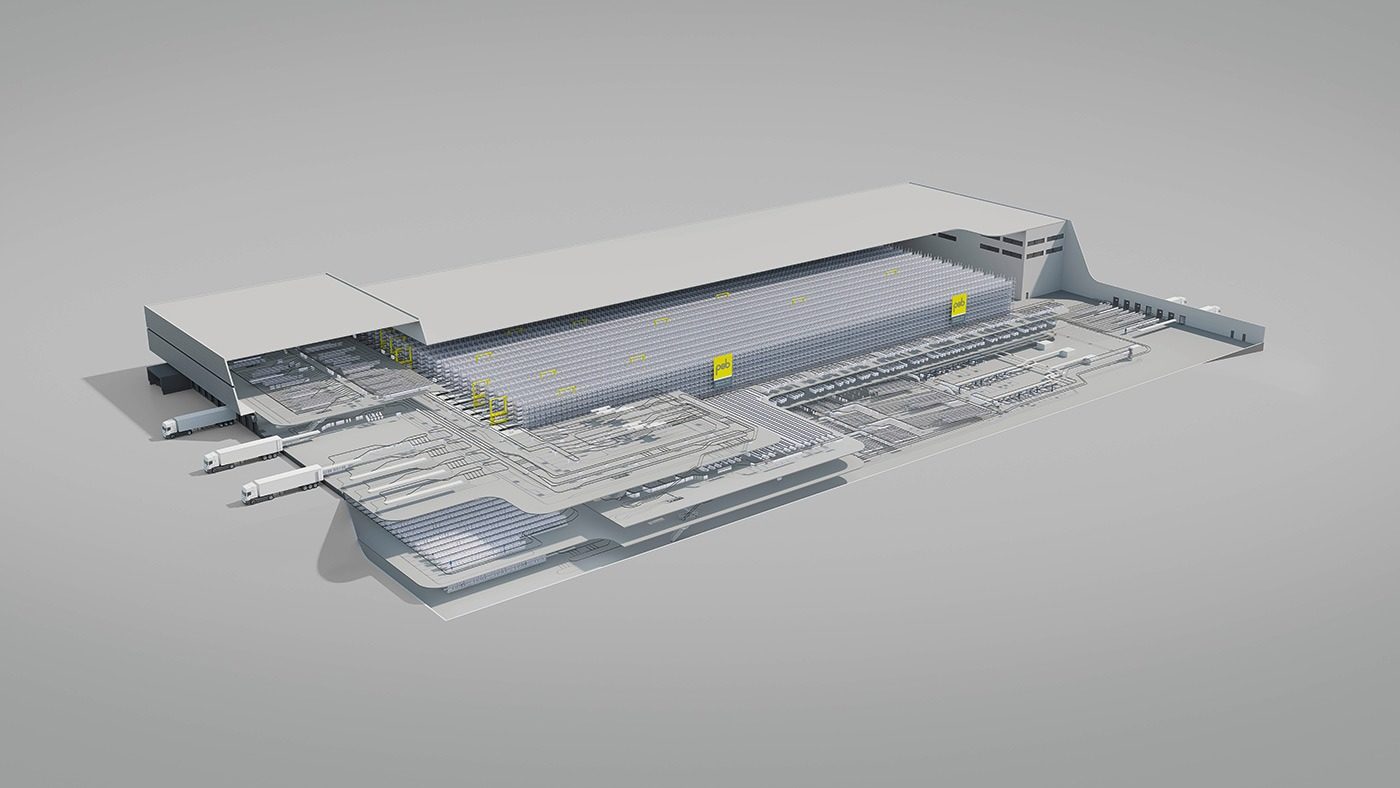

Distribution center for GOH

MANGO group of Spain is one of the world’s leading fashion retailers, with more than 2,000 stores and franchisees as well as a strong online business.

Customer:

MANGO – Punto Fa, S.L.

Palau-solità | Spain

System:

High bay warehouse (20 aisles) with runloader AS/RS stacker cranes, trolleyless overhead conveyor systems for connecting the functional areas, psb micro trolley system mtr for buffering, sorting and sequencing of single items, automated goods-in and goods-out processes.

Design criteria

psb intralogistics implemented for MANGO one of the largest and most modern intralogistics systems in Europe. From that location, the company supplies the stores and the e-commerce distribution center. The DC has the capacity to store 8 million garments on hangers, and to pick and prepare more than 1 million items for shipment daily.

The solution

The systems solution for this project is completely automated: from goods-in to inhouse material flow and warehousing to sorting/sequencing and preparation for shipment. These processes are complemented by manual operations such as value added services and packaging.

Storage and retrieval are performed by 25 meter high AS/RS stacker cranes type runloader in a high-bay warehouse that has a capacity for 8 million parts. Via an intelligent material flow, the psb micro trolley system mtr handles the automatic order picking to the packaging stations in the exact sequence. Trolleyless overhead transport systems connect all logistics areas, from goods-in to warehouse and sortation to packaging and dispatch. These processes are controlled by selektron, psb’s material flow control software.

Gallery