Multi Access Warehouse: Number 1 in performance and flexibility

The psb solution differs from conventional warehouse configurations by the larger number of tote lifts. These can also be accommodated in any position within the storage aisles to save space. If there are additional performance requirements, the number of tote lifts can be easily increased. Furthermore, the lifts can be equipped with two load-handling devices (LHD) and the aisles with up to two shuttles per level. This shuttle system is particularly effective in long and tall warehouses with a high capacity and has enormous power reserves ready.

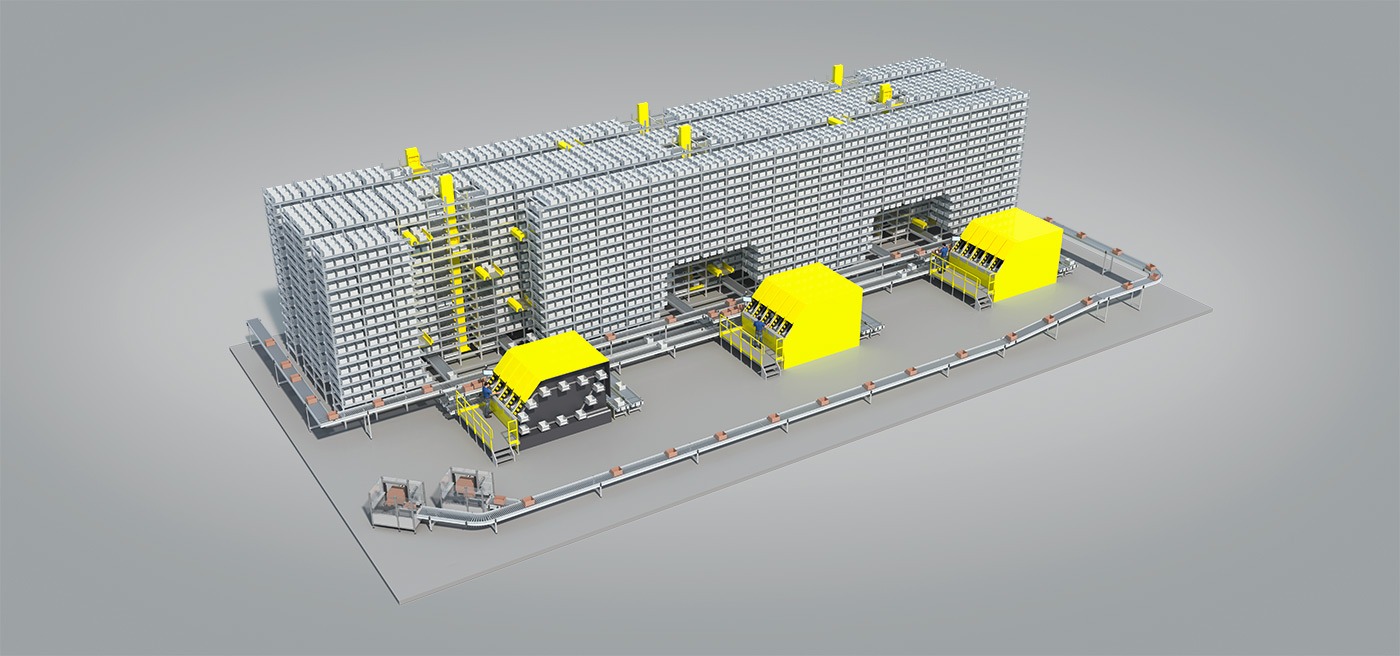

Shuttle system with direct connection: Multi Access Warehouse

With the configuration of the external conveyor technology adapted to the warehouse concept, the incoming goods and picking areas can be connected directly to the Multi Access Warehouse shuttle system. The shuttles deliver LHDs to the lift in a targeted manner, which steers the LHD to the designated workstation without crossing.

It is very easy to expand the storage capacity, either by increasing the number of aisles or lengthening them. The tote lifts, which are easy to add, always guarantee a consistent average aisle performance or enable performance increases of the shuttle system that are adapted to the capacity increase.

vario.sprinter: proven shuttle system technology

The vario.sprinter shuttle from psb masters the handling of a wide variety of LHDs such as cartons, totes and trays up to a weight of 70 kg. The energy supply via supercapacitor, efficient energy recovery systems and control via Wi-Fi characterise the innovative shuttle system.

There is even more flexibility with the shuttle system vario.sprinter flex

vario.sprinter flex handles with its width-adjustable gripper arms LHDs of different length and width. This particular type of shuttle is combined with a racking concept with flexible storage location configuration. This enables different LHDs to be handled on the same storage level or even in the same location and thus also increases the flexibility and efficiency of warehouse use.

Further strengths of the Multi Access Warehouse shuttle system

The availability of stored goods is significantly increased through system redundancy provided with multiples of LHD lifts and conveyor technology for storage connection. Each LHD can be delivered to several lifts by several shuttles and conveyed out of the warehouse via various conveyor technology connections. An intelligent security concept also ensures that the respective warehouse aisle can still be used in the event of maintenance access – even if some levels or individual lifts have been deactivated.

The psb shuttle system Multi Access Warehouse guarantees very efficient use of the warehouse in off-peak periods, with simultaneously large power reserves for peak times, as individual lifts, conveyor technology sections and the associated picking areas can be deactivated at any time. Nevertheless, every LHD in the warehouse can be easily accessed in all operating scenarios.

The possibility of integrating the incoming and outgoing conveyor technology on any desired storage level offers a high degree of flexibility when planning the layout of your shuttle system. In this way, each project can be adapted to the specific conditions of the building, material flow, etc. This ensures the optimal arrangement of your warehouse and the upstream and downstream handling areas.

Find out more about the Multi Access Warehouse shuttle system in use and its integration into the respective overall intralogistics system in these Best Practices: