Sustainability at psb intralogistics

For many years, »green efficiency« – the intelligent and sustainable use of resources – has played an important role at psb. We think »green« both in the design and in the implementation of our intralogistics systems.

Positive figures thanks to green intralogistics

The importance of the energy efficiency of intralogistics systems has increased steadily in recent years. This development goes hand in hand with the concept of life-cycle costings, which has replaced the need to look at pure procurement costs. psb intralogistics offers a wide range of efficiency measures: from efficient system design to needs-based system control to energy recovery.

Green light straight from the design phase

Even before implementation, we develop tailor-made, sustainable solutions to make our intralogistics »greener«. This can include the concept of a modular system design, enabling conveyor elements and system components to be connected as required. Functions at the logic IT level, such as for combining orders into appropriate batches, can also be optimised in advance.

Constructive in matters of construction

In the implementation phase, we check that task management is consistent and efficient, using special mechatronic components. In line with the motto »recovery instead of heat loss«, this permits energy recovery in relation to the drives, for example. The use of effective high-efficiency motors (HEM) or lightweight mechanical components can increase efficiency considerably.

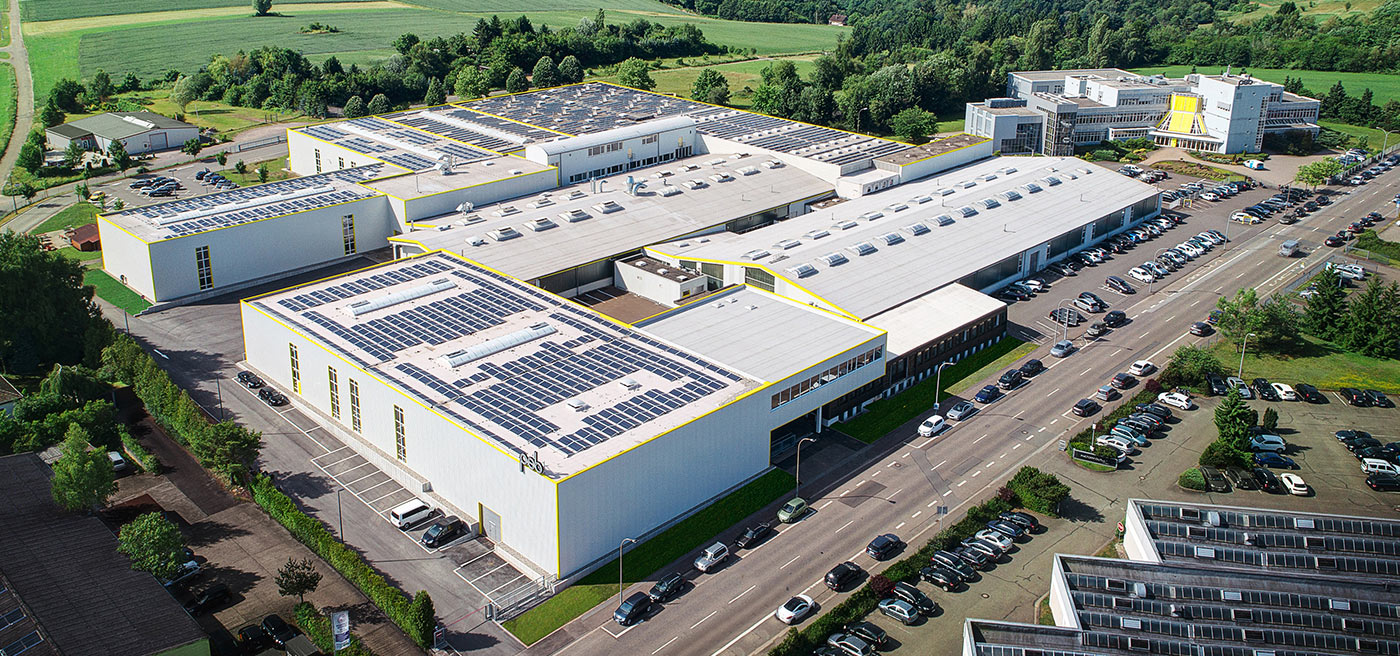

Sustainable company site

Our claim to having the greenest possible intralogistics also means that we think and act sustainably within our own company. In addition to reducing our electricity consumption, the large photovoltaic system on our halls and our own combined heat and power plant form the core of our energy-saving measures.

With these two systems, we supply our buildings and our paint shop with energy-efficient heat and cover 75% of our electricity needs from our own environmentally friendly production. We save around 600 tons of CO2 per year.

Producing our own electricity not only benefits the environment, but also our employees: They have the opportunity to »fill up« with electricity free of charge at the company’s own charging stations.