Next

Automated returned item

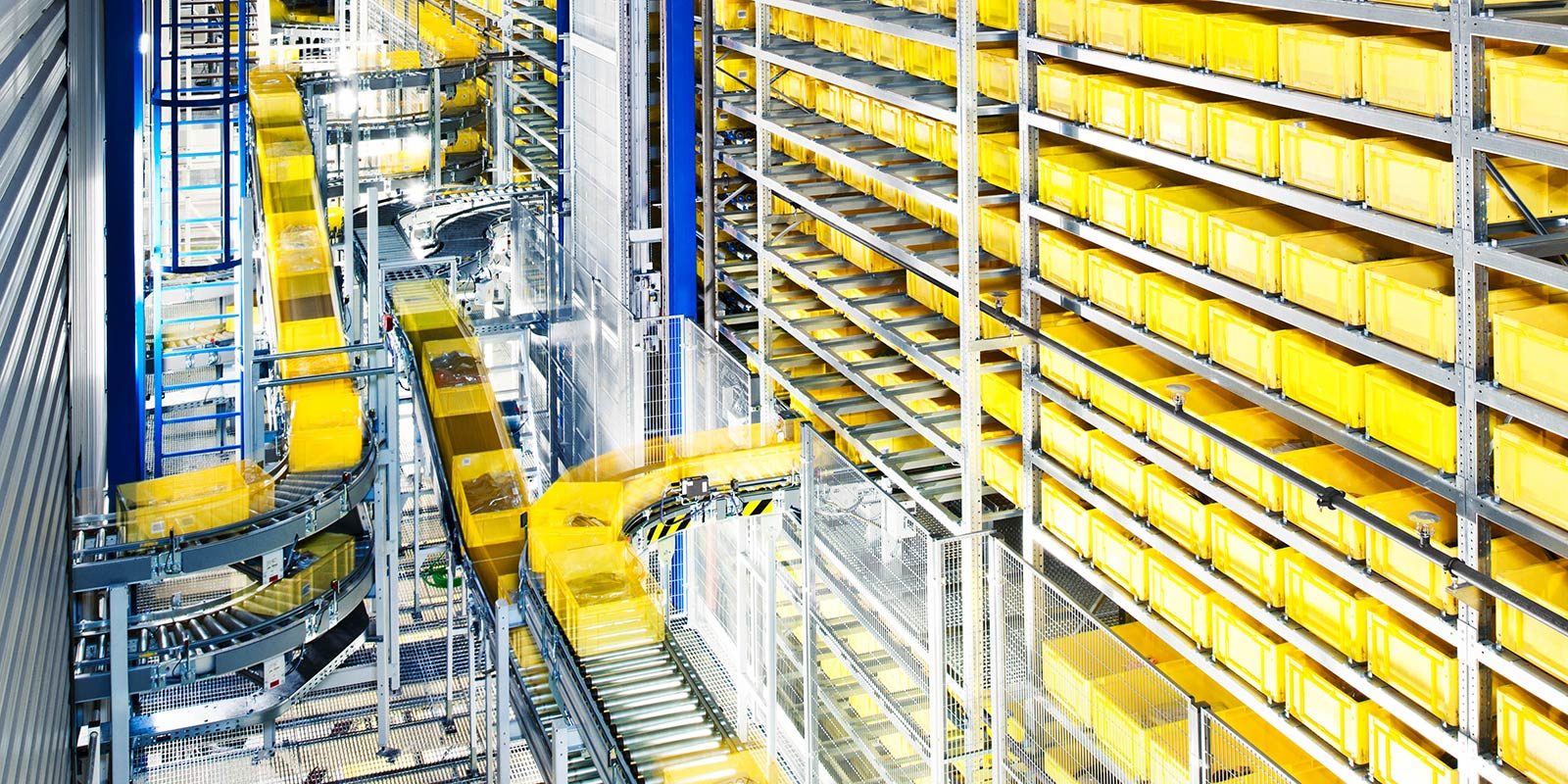

storage and picking system »RSPS«

The Next retail chain was launched in February 1982. Today, Next trades from more than 500 stores in the UK plus Eire and over 180 stores in more than 30 countries overseas. In 1999 online shopping was introdouced. Next still continues to improve customer service, introducing new initiatives such as next day delivery as standard to orders placed before 9 pm. At the Next warehousing location, South Elmsall, returned mail-order items are buffered and directly picked for online shopping and store retailing.

Customer

Next Distribution Ltd.,

South Elmsall, West Yorkshire | UK

System

Automated warehouse with more than 100 vario.sprinter shuttles, 16 rotapick order picking stations, 12 replenishment (top-up)stations, conveyors, WMS with special functions and selektron SCADA

Design criteria

In contrast to large pick quantities for the retail stores, the e-commerce operation requires a fast growing number of small orders delivered to private households. This so-called »atomization«, with extremely short processing times, plus the growing number of returns, involves all warehouse processes, and demands a highly efficient returns management.

The solution

The new solution allows for a well-coordinated integrated intralogistics system, by combining warehousing and order picking operations. Special focus is put on a very high degree of flexibility, redundancy and system availability. In the system installation, more than 100 psb vario.sprintershuttles are operated; they are connected, via a dynamic conveyor system, with 16 psb rotapick high performance order picking modules and 12 tote replenishment (top-up) stations. The entire system solution is designed with respect to sustainability, utilizing, among others, ultra-modern modules for energy recovery. Warehouse management and organization are controlled by the psb selektron WMS control system. It comprises all aspects of stock handling, e.g., the administration of the order picking batches, the permanent supply of the rotapick stations, replenishment of the storage totes, plus displaying and communicating key performance indicators. The installation is monitored by the psb selektron SCADA visualization system.

Gallery