kohlpharma

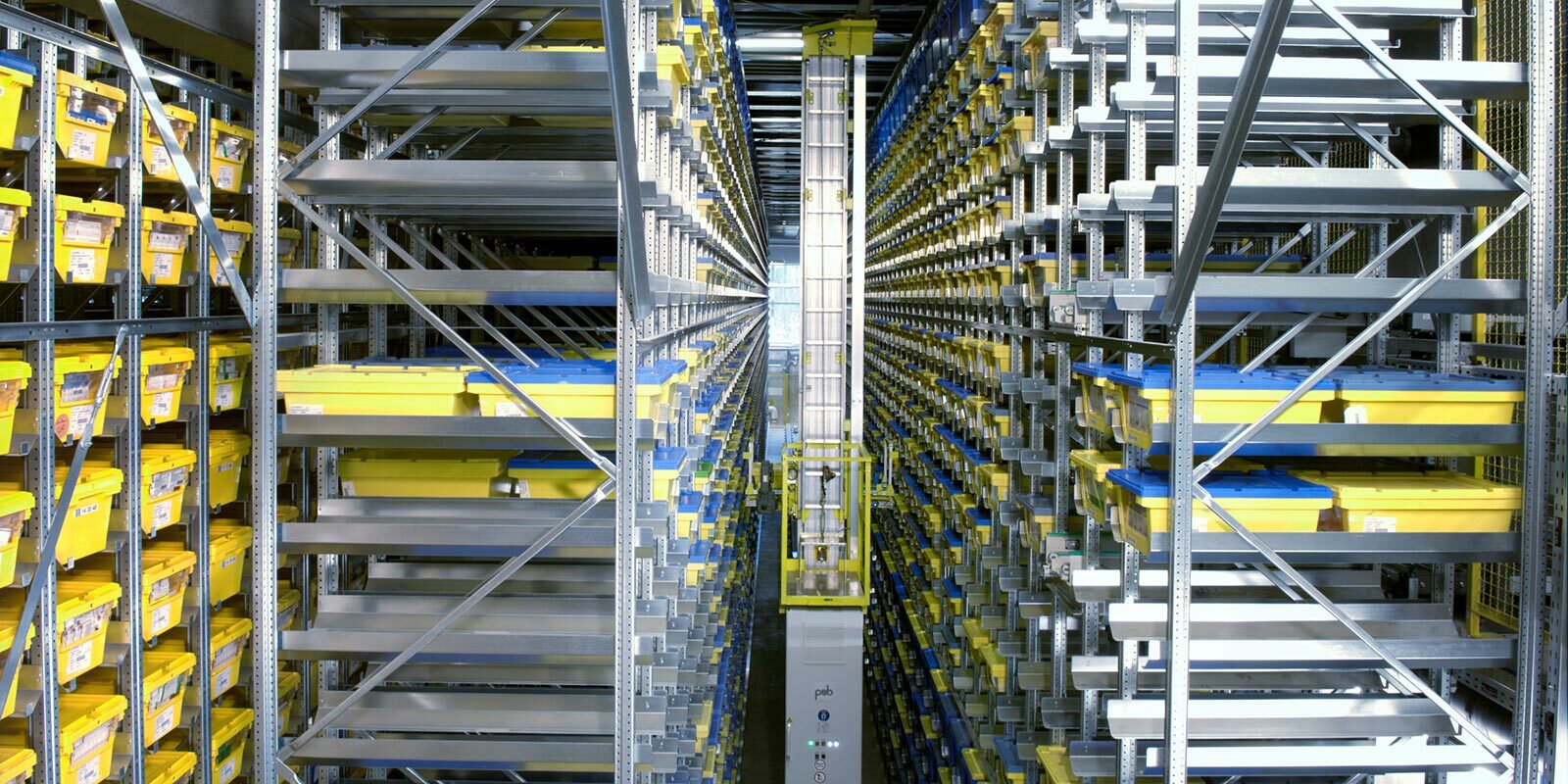

Automated warehousing system for

pallets and bins in the pharmaceutical industry

kohlpharma, supplier to pharmacies and pharmaceutical wholesalers, was founded 1979. Today, the company is one of the leading importers of pharmaceuticals in Europe.

Customer:

kohlpharma GmbH 66663 Merzig | Germany

System:

6 sprinter and 3 maxloader AS/RS stacker cranes, shuttle car, conveyor system, selektron LC (system control), selektron SCADA (visualization) and selektron WMS (Warehouse Management System)

Design criteria

Top priority is to supply the kohlpharma customers with high-quality products, economically and at the right time. In order to satisfy these requirements permanently, a warehouse for bins and pallets had to be installed in an existing building. The objective was to maximize the utilization of space, and to implement the installation, as far as possible, with already existing systems. Furthermore, the works had to be carried out during operations.

The solution

The warehouse area comprises of a doubledeep bin storage (6 aisles) for bins of different sizes, and a pallet storage (3 aisles). The bin and pallet conveyor technology is complemented with new sprinter and maxloader AS/RS stacker cranes, plus a shuttle car.

Four types of bins of different sizes are handled, by especially designed load handling crane devices. If a bin in the rear has to be taken out of store, the bin in front has to be relocated; this is done automatically by the selektron WMS Warehouse Management System software.

Another new feature is the interface to the customer’s ERP system (Enterprise Resource Planning) and the visualization of the system through selektron SCADA.

The reorganization was carried out very smoothly so that kohlpharma’s customers hardly realized any changes. Yet, it was stated that dispatch (shipping) efficiency has been improved considerably.