psb intralogistics

Smart solution for centralised tool management

psb intralogistics is a leading European company in the intralogistics sector which plans and implements customised integrated systems. Due to the extraordinarily high internal added value, the system components are manufactured in the company’s own machining centre at nine CNC machines.

Customer:

psb intralogistics GmbH,

66955 Pirmasens | Germany

System:

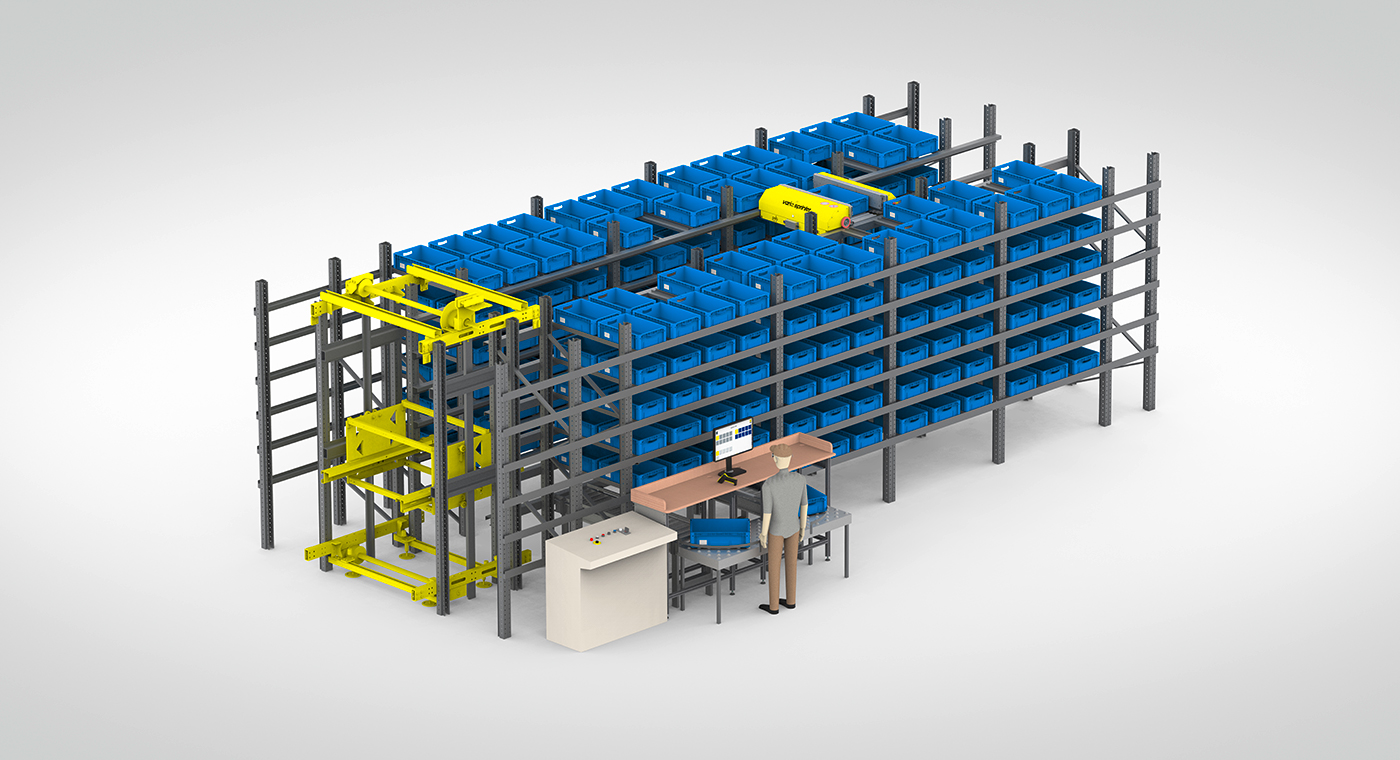

microstore with vario.sprinter shuttle, shuttle lift and order-picking workstation.

Design criteria

Optimisation of manufacturing processes

Historically the tools had been stored manually without central organisation or systematic inventory management. The machining jobs were manually assigned to the respective machine and the list of the tools to be taken out of storage was created manually as well.

The manual and decentralised management and provision of tools was error-prone, time-consuming and expensive. Therefore, these processes should be centralised, digitalised and automated.

The solution

Centralised storage of tools

The main components of this installation are a rack, which is scalable in height and length, a vario.sprinter shuttle, a shuttle lift and an order-picking workstation. Through the scalability of these elements, the compact warehouse could be optimally designed onto the available space of 13 x 3.5 x 5 m. The new tool warehouse at psb has a capacity for 350 totes of 600 x 400 mm. Up to 5,000 tools can be automatically stored and managed. With a performance of 50 storage and retrieval operations per hour, the microstore offers capacity for future growth.

Automated tool management as key to increasing efficiency

The microstore tool warehouse is managed and controlled by the integrated PLC control via the picking workstation. The different system platforms involved in the manufacturing process are linked together by a software module, that collects the data necessary for the management of the tools and makes them available to the operator of the tool warehouse. As all relevant information is digitally available at the picking workstation in the warehouse, the operator can transfer the tool data from the production scheduling system directly to the warehouse control system for the generation of retrieval orders.

Gallery