psb pouch sorter: automatic sorting system to simplify order picking

The psb pouch sorter is an intelligent sorting system that transports and sorts single items in pouches. This order processing approach enables more efficient order picking and despatch preparation as well as buffering of goods and returns. In addition, consolidation of multi-item orders is simplified considerably.

With the pouch sorter system, a multitude of advantages of overhead transport systems can be transferred to the handling of flat-packed items like shirts, shoes or other articles that are processed in e-commerce and mail order. This way, the manual workload is minimised and handling costs are reduced. In combination with the psb autopouch, even very complex sorting tasks can be carried out without manual intervention.

In e-commerce, mail order and retail operations, the use of pouch sorters significantly improves the sorting of ordered merchandise. They enable simple, fast and cost-effective handling, which optimises the shipping process.

The pouch sorter can demonstrate its particular strengths in the handling of returns. The temporary storage of returned items in the buffer eliminates the need for time-consuming sorting into the original warehouse. When the goods are reordered, they can be called out of the returns buffer very efficiently.

The modular structure of the automated sorting system provides for an easy step-by-step realisation concept. This flexible logistics solution allows additional modules to be seamlessly integrated into existing systems.

A pouch sorter provides major advantages both as stand-alone solution and as supplementary component to existing intralogistics systems. This approach keeps costs low, reduces labour-intensive operations and minimises errors, which significantly increases the efficiency of the shipping process.

Innovative zero-touch solutions thanks to the psb autopouch

The pouches can be unloaded either manually or fully automatically with the psb autopouch. In the fully automatic version modified pouches are utilised that can be unloaded automatically without stopping by means of a closing strip at the bottom edge. This can be done at almost any point in the system, which enables simple sortation into a variety of target destinations or onto target conveyors.

Thanks to this innovative technology, automatically unloading pouches do not require any additional closing stations, which reduces the expenses for loading and unloading stations and enables the implementation of modern zero-touch solutions.

Your intralogistics system, individually designed for your requirements

At psb intralogistics, we focus on customised solutions, rather than standard approaches. We work out each concept especially for your individual demands.

Through an in-depth analysis and close cooperation with our customers we ensure that each intralogistics system perfectly matches the respective requirements. Our aim is not only to maximise efficiency, but also to ensure flexibility and future reliability.

Modular concept

The modular design and easy adaptability make the system economically attractive for small and medium-sized installations as well as large-scale operations.

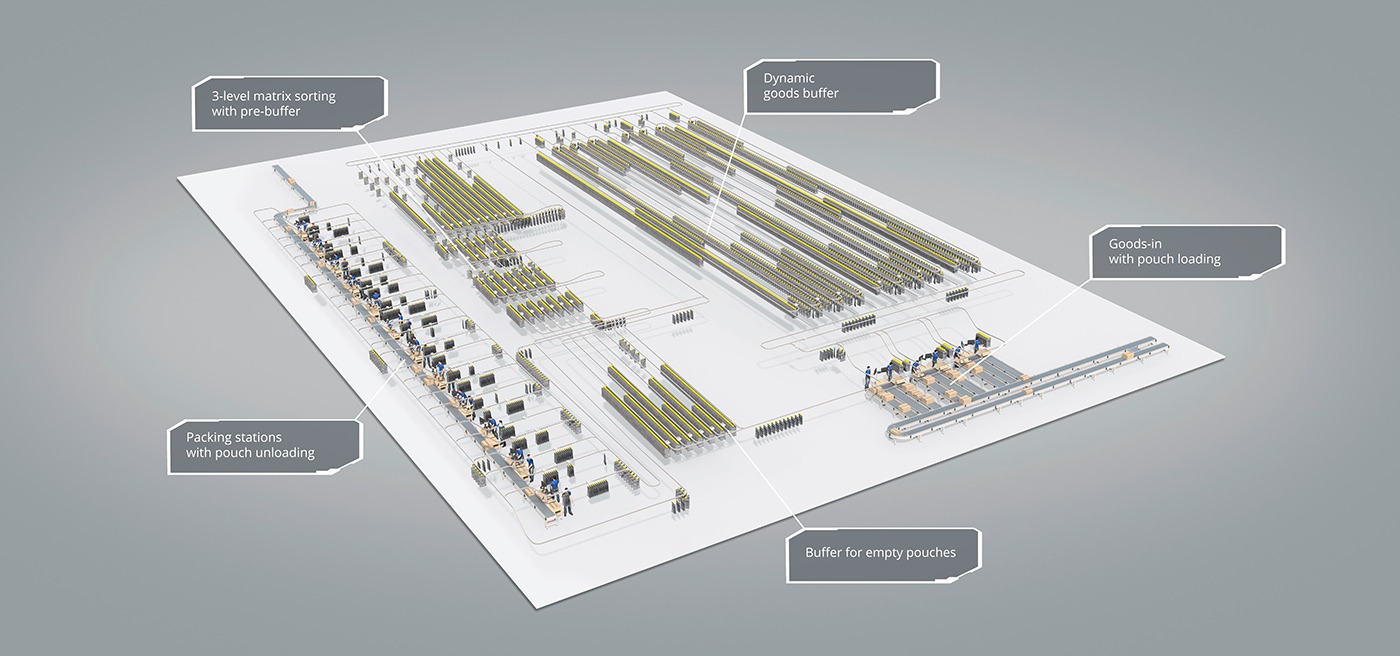

The system modules interact seamlessly and are matched specifically to the customer’s needs. This comprises the processes for goods feed-in and pouch loading (also fully automated) plus overhead transport, static or dynamic buffering, matrix sorting in exact sequence and pouch unloading (also fully automated).

Depending on the respective project, various upstream and downstream areas may be added to the intralogistics installation, such as inbound goods and returns, quality check, value added services, packaging as well as other customised additional features.

Experience the pouch sorter live: in the psb Technology Center

In addition to numerous psb pouch sorter systems that are successfully operated by our customers, we run a large installation on 1,200 square metres in our Technology Center. We cordially invite you to visit that state-of-the art intralogistics system at our company headquarters in Pirmasens and to talk with us about your individual project approach.

Individual design and consultation: meet our experts!

"*" indicates required fields

Gallery