Intralogistics for medical technology: B. Braun

Intralogistics for medical technology: B. Braun

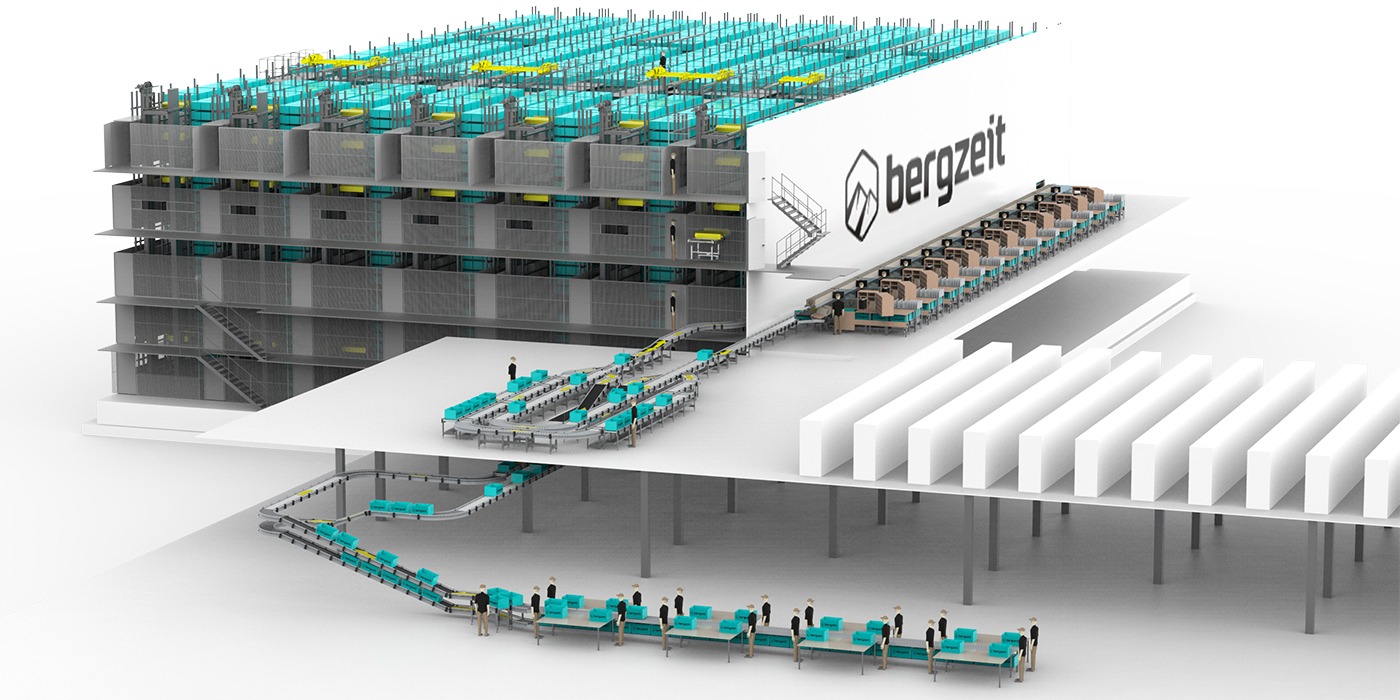

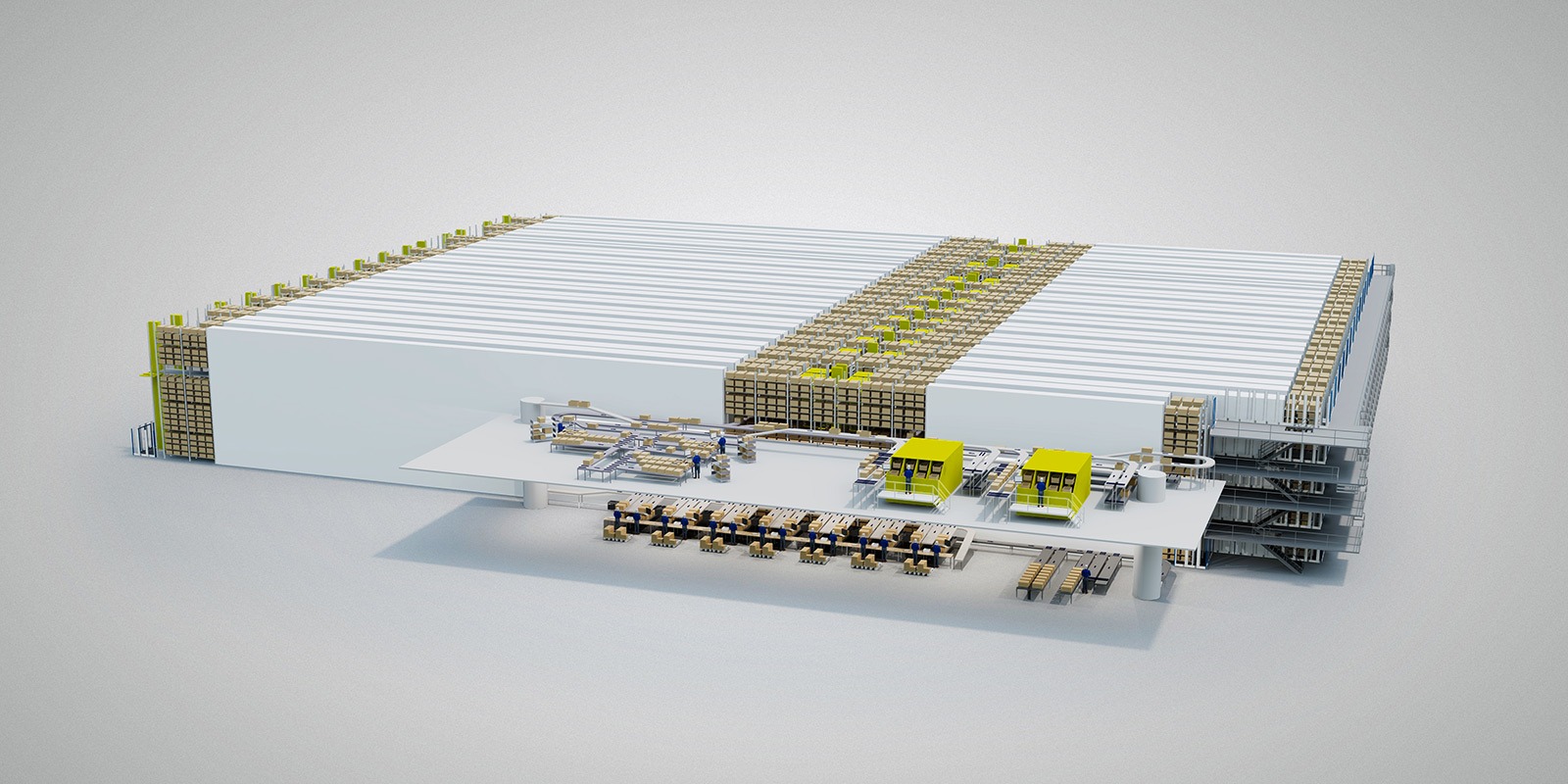

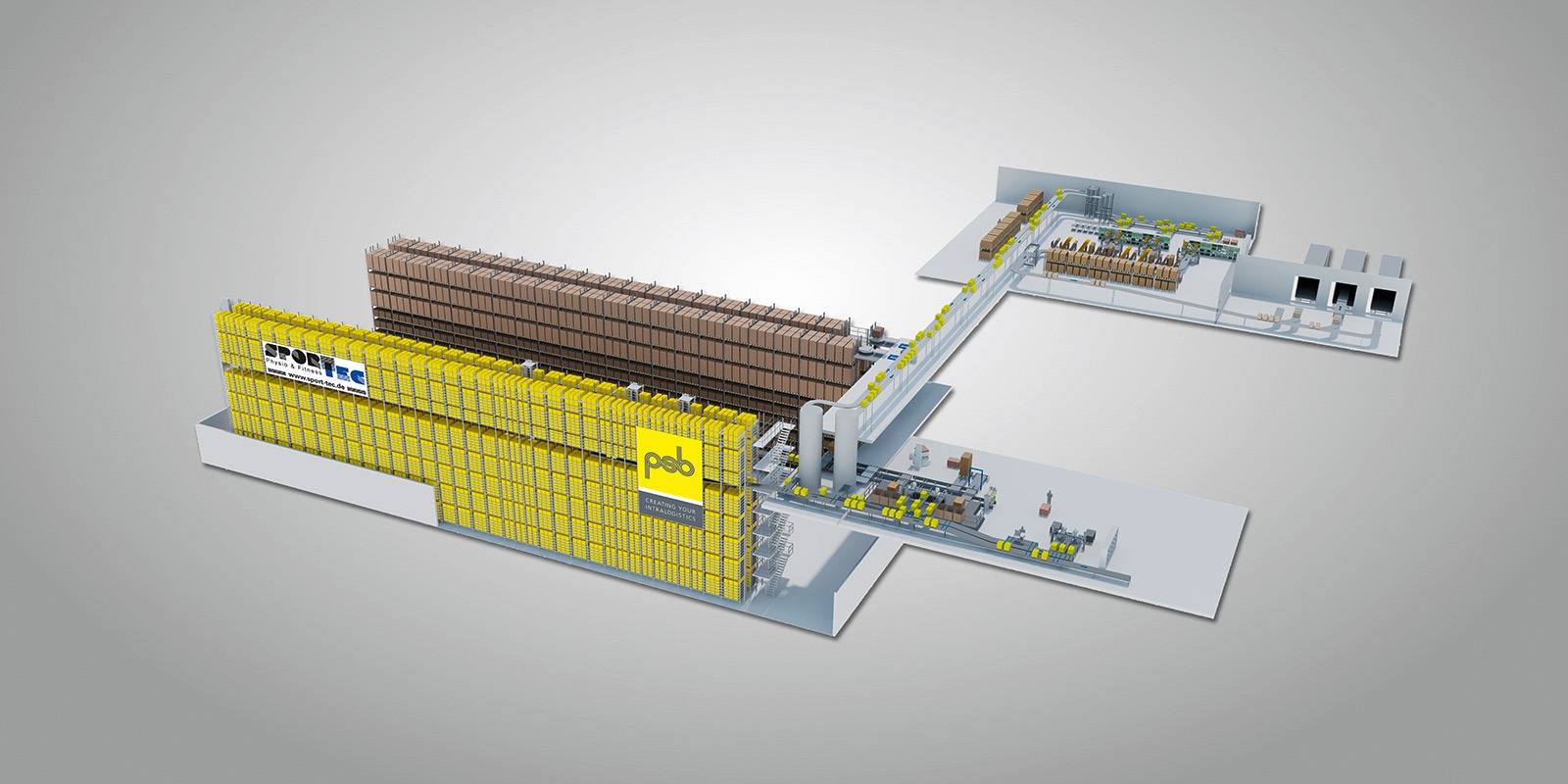

B. Braun is one of the world’s leading manufacturers of medical technology and pharmaceutical products. At its headquarters in Melsungen, the company has been growing steadily for years – and hence the demands on internal logistics. To meet these demands, and to support the company’s further development, psb was contracted to implement a shuttle warehouse for supplying the production facility.

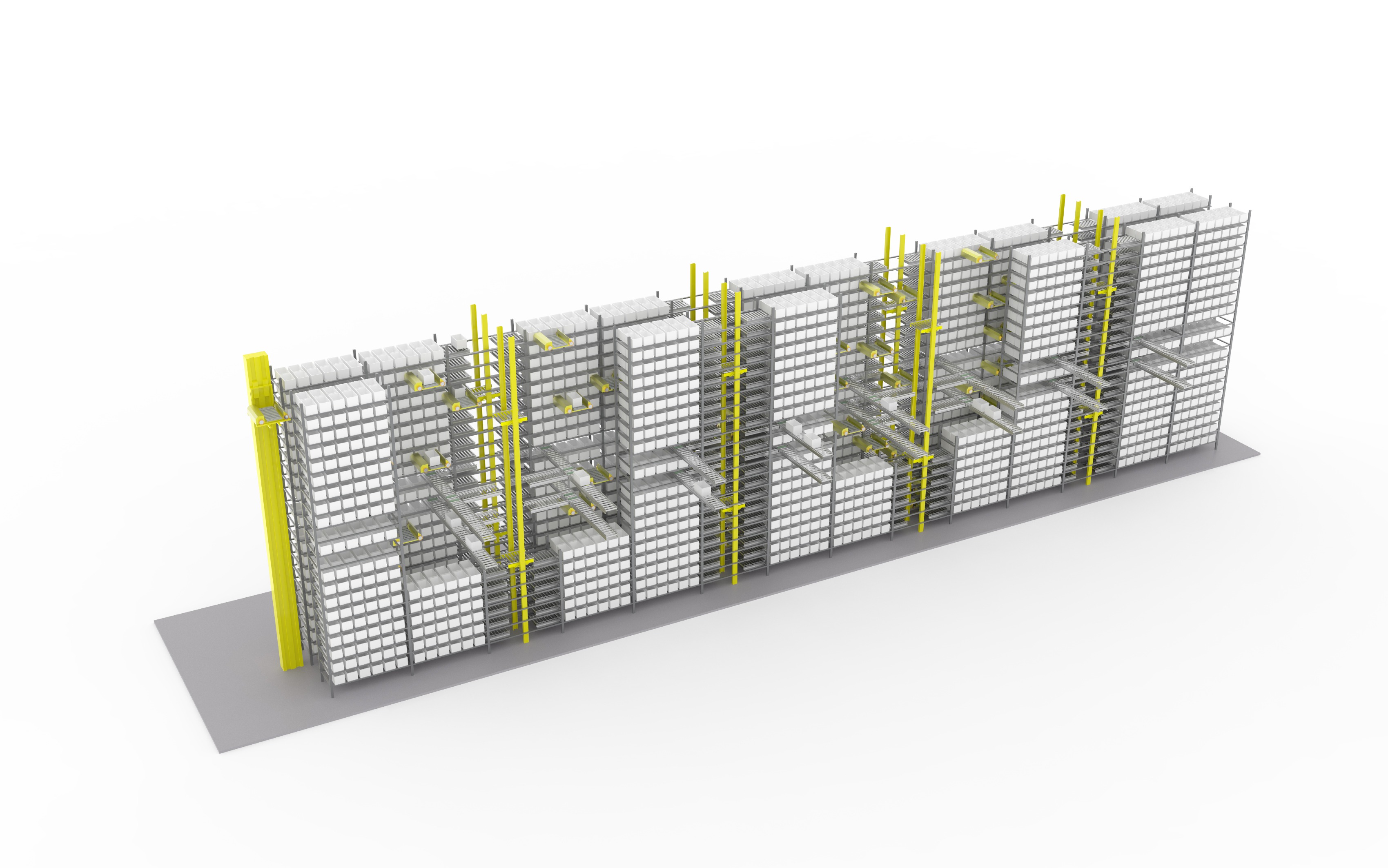

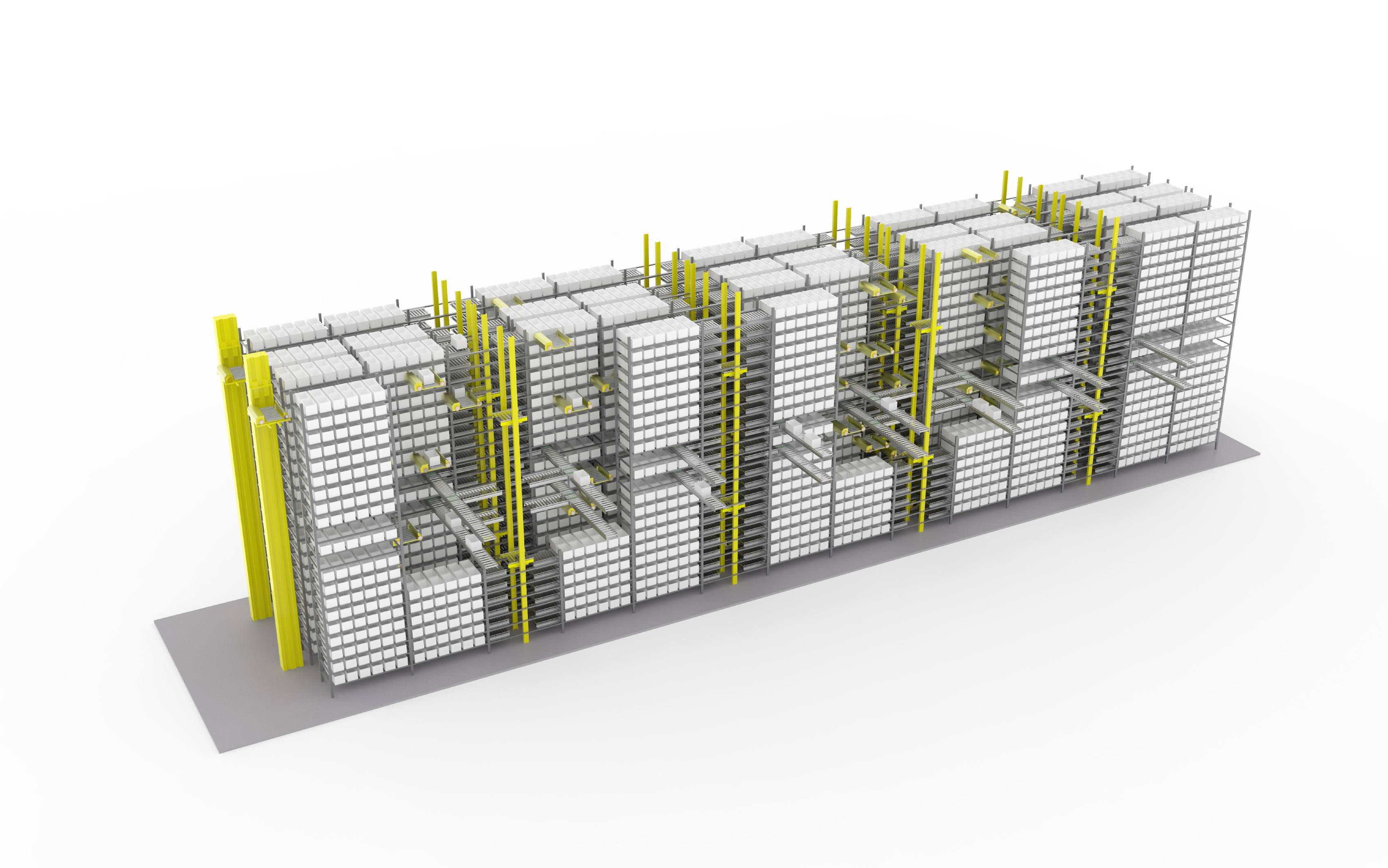

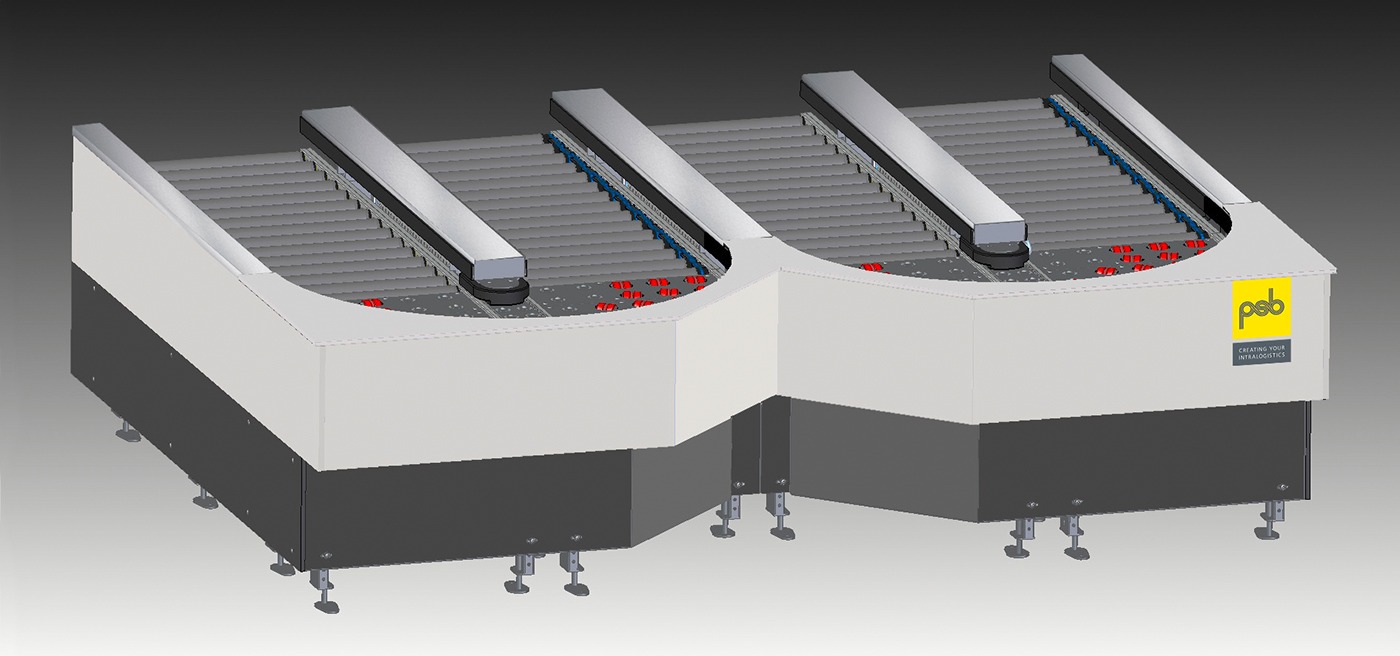

Since only a very limited amount of space was available in the existing building and the newly constructed extension, optimal use of the space was a decisive factor in working out the concept. With the psb Multi Access Warehouse, the entire building length of 55 m could be used for the warehouse cube, which is only 8.5 m high. The work areas arranged on the sides enable ideal connection to both the goods receiving area and the downstream production areas.

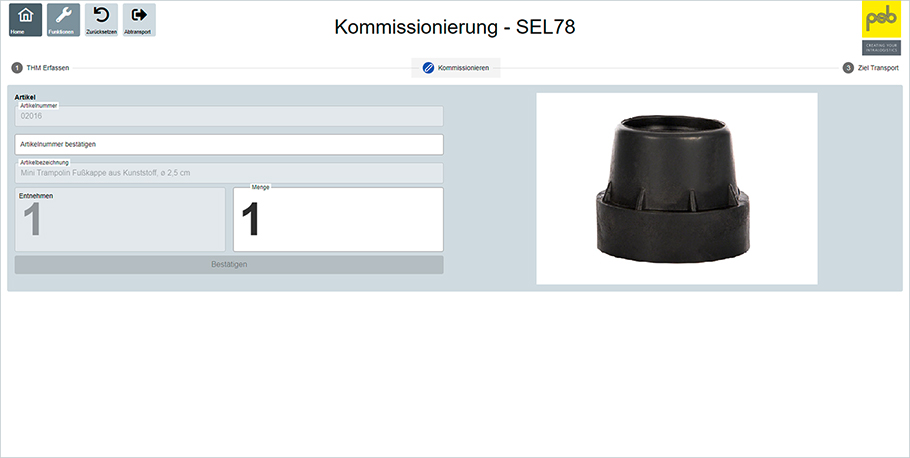

The new three-aisle shuttle warehouse has around 18,500 storage locations and is designed to store up to 600 full containers in and out per hour. The special feature of the system is its exceptionally high storage density, which is achieved through a combination of stacking and pairing: Low containers are stacked before storage, smaller sizes are combined into »pairs« and then stored in the warehouse in a depth-optimized manner. Pairing is carried out fully automatically on the conveyor system and enables extremely efficient use of the available space.

The successful implementation of this project and the system installation, which has been in operation since summer 2025, have contributed significantly to psb being awarded the contract to build another shuttle warehouse in the region this year.